Your Trusted Partner in Vehicle Lifts & Equipment

- Expert Knowledge & Advice

- Excellence in design

- Total Safety

Quality car lifts to suit every type of workshop

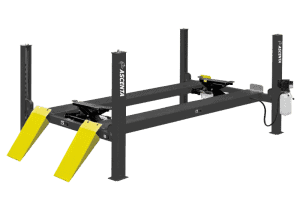

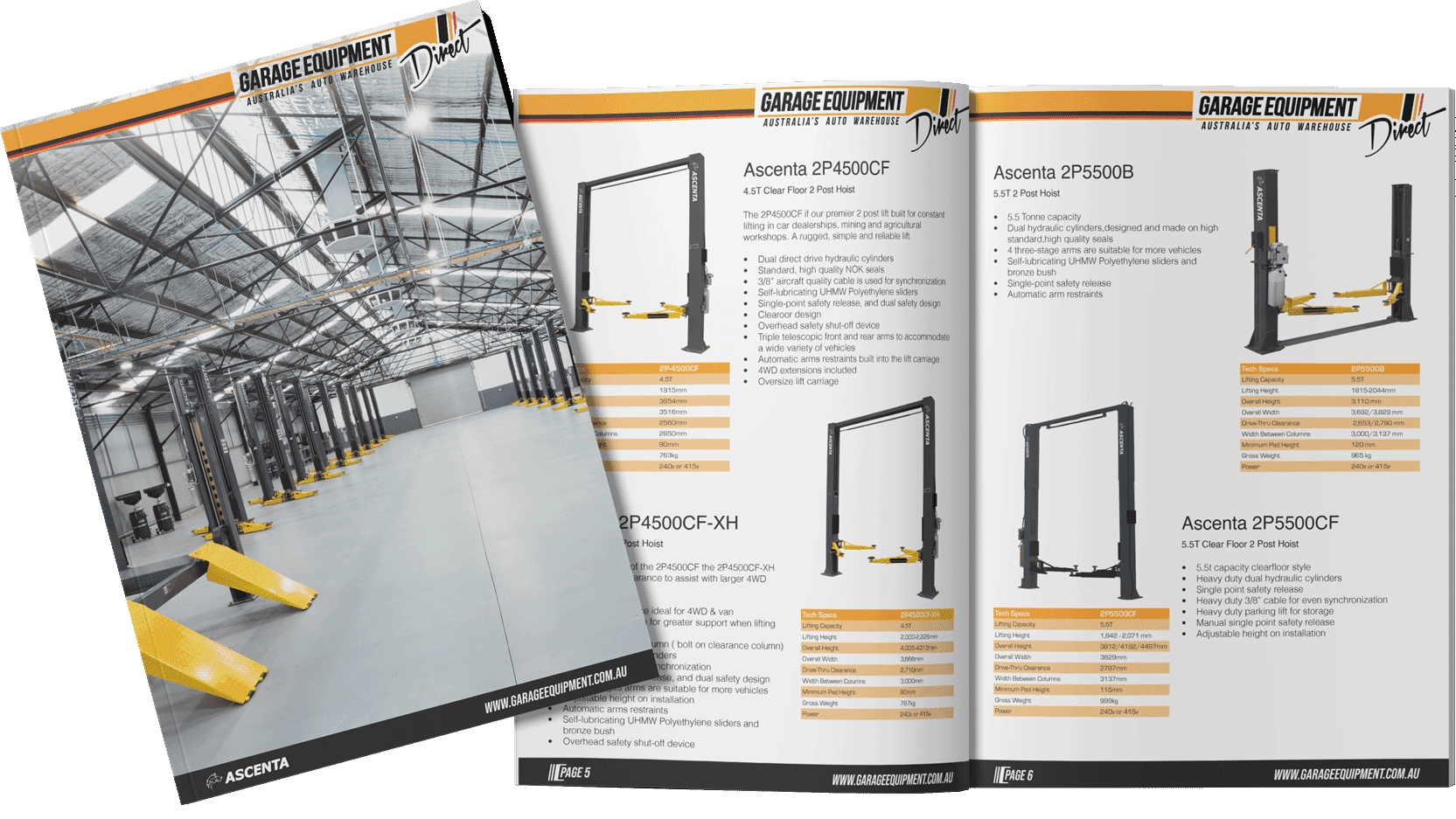

Whether you’re a professional garage mechanic or a home enthusiast, you’re probably aware of the massive difference a workshop hoist can make to your productivity. Garage Equipment carries a wide range of high-quality car lifts to suit the needs of any thriving commercial garage or dedicated car enthusiast. We offer 2 post car hoists, 4 post car hoists, alignment lifts, car storage and parking lifts, mid-rise lifts, car scissor lifts and more.

All Garage Equipment car lifts are the product of decades of engineering experience and innovation. Plus you’ll benefit from having our friendly and knowledgeable team of car lift product experts on call.

View our complete range of jacks, wheel service, and workshop equipment

Whether you’re looking for workshop equipment like work benches, tool boxes and oil drains; wheel service equipment including tyre changers, wheel balancers, brake lathes, and wheel alignment systems; workshop jacks, floor jacks, or jack stands; or even industrial-grade parts washers, Garage Equipment is the first name in quality workshop equipment.

Quality workshop products and expert advice, at the right price

Welcome to Garage Equipment

Since being established in Brisbane in 1994, Garage Equipment have supplied hundreds of automotive workshops right across Australia.

We’ve put together an experienced team who are committed to providing outstanding service to the automotive service industry across Australia. With years of industry experience, they have the know-how to give you the quality garage equipment you need at a competitive price.

Whether you’re a home car enthusiast or a car workshop business, in need of a complete workshop fit out or a single piece of quality workshop equipment, Garage Equipment can help.

To help you get the best ROI from your vehicle hoist, the Garage Equipment team have put together the below product catalogue to give you a clear snapshot of your options.

Jonathan

Garage Equipment